Humanity is not treating Planet Earth well. In 2016, the total amount of waste that was generated by all economic activities and households across the EU-28 topped 2,500 million tonnes. This amount has grown in recent years. According to the OECD, the amount of materials extracted, harvested and consumed worldwide has increased by 60% since 1980!

Earth Overshoot Day – the day by which we have used more ecological resources and services in one year than our planet can renew within that same year – comes earlier and earlier with each passing year. For example, in 1980, Earth Overshoot Day landed on 4 November; in 2000, Earth Overshoot Day took place on 23 September; and in 2017, it came as early as 2 August. We need to learn to produce more with less.

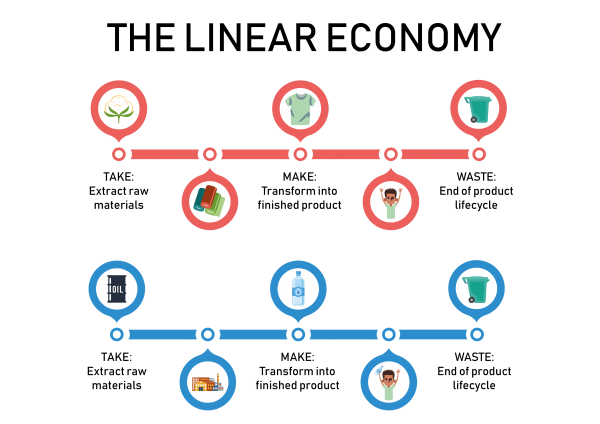

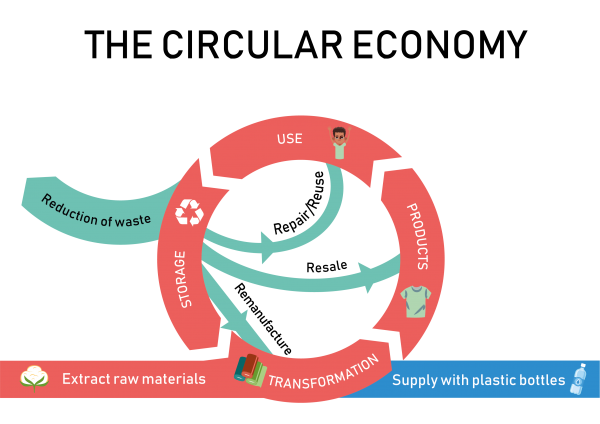

The circular economy concept is part of the solution to this challenge. The objective of the circular economy is to replace existing linear models (those with a “take-make-waste” nature) with circular models. In linear systems, raw materials are extracted, processed into finished products and become waste shortly after being consumed. A circular economy, however, aims at limiting both the extraction of raw materials and the production of waste by working as a closed system, thereby reusing materials and conserving energy. Check out the graphic below for how this works when applied to the clothing and plastic bottle industries, and how plastic bottles can actually be used to make T-shirts!

Five Types of Business Models

In its report Circular Advantage, Accenture identified five types of business models that companies can apply to implement a circular economy:

1. Resource recovery

The resource recovery model aims at reusing resources or energy from disposed products or by-products. The concept of industrial symbiosis is a good example of these models: in an industrial park, or when two industries are nearby, one can sell a by-product to another one. In the H2020 paperChain project, in which LGI participates, five cases of industrial symbiosis are demonstrated (see table below). In each case, a waste from the pulp and paper industry receives a second life by being used to produce another material in a different industry (thus eliminating a product in the production process altogether).

Paperchain pulp and paper waste applications

2. Circular supplies

In this model, supplies (materials or energy) used as inputs are replaced by renewable, recyclable or biodegradable resources. IKEA provides a good example. In 2014, it purchased a wind farm in Illinois as part of its effort to produce more renewable energy than it will have consumed by 2020. This project is expected to produce the equivalent of 130% of the energy used by all US-based IKEA stores.

3. Product life extension

Here, companies try to extend the lifetime of a product through remanufacturing, repairing, upgrading or re-marketing. For instance, the company FAIRPHONE commercialises a modular phone “meant to last.” It is composed of replaceable modules, making it easy to repair.

4. Sharing platforms

The sharing platform business model is based on the sharing of goods and assets. Such products are either not frequently used by a person or a company, or have a low ownership rate. The sharing economy is developing fast and examples are numerous. One example which comes to mind is BlaBlaCar, which connects car owners and travellers so that they can share a ride.

5. Product as a service

In this business model, customers don’t buy a product but use it through a lease or a pay-for-use arrangement. This model encourages companies to produce qualitative products that last longer and can be easily repaired. An example here is Rolls-Royce’s “power by the hour,” in which the company sells the hours its plane turbines are in the air, rather than selling its aero engines directly. Rolls-Royce provides a service in the form of support and maintenance, ensuring the aero engines can continue to deliver power.

The five types of business models are not mutually exclusive and can be combined for maximum effect. FAIRPHONE’s business model, for example, combines the “product-life extension” model (see example given above) with that of the “circular supplies” model, as it sources its key materials more responsibly (i.e., tin, tungsten and tantalum). This not only further reduces the waste it produces, but the improved environmental conditions also contribute to better working conditions.

In order to make a successful transition to a circular economy, various barriers must be overcome. In our next blog post, we’ll discuss what some of these barriers are, as well as present several enablers for implementing your very own model.

The views and opinions expressed in this blogpost are solely those of the original author(s) and/or contributor(s). These views and opinions do not necessarily represent those of LGI or the totality of its staff.

FOLLOW US